- Manual Cleaning

FlexiPump™ Independent Flushing System

The FlexiPump Independent Flushing System helps assure copious flushing of internal device channels and lumens during pre-cleaning.

Learn More

- PureChannel Flush Touchless Auto Dispenser

- PureStation Sink Insert

- PureStation Dedicated Eye Sink

- PureStation Mobile Cart

- PureStation™ Mobile Cart Revital-Ox® RESERT® Bracket

- PureSteel Mobile Soaking Station

- InstruSafe XL Transport Container

- PureSteel XL Transport Container Cart

- PureSteel XL Transport Container Tiered Cart

- SuperDART® ONE PASS™ Brush

- Healthcare Sinks

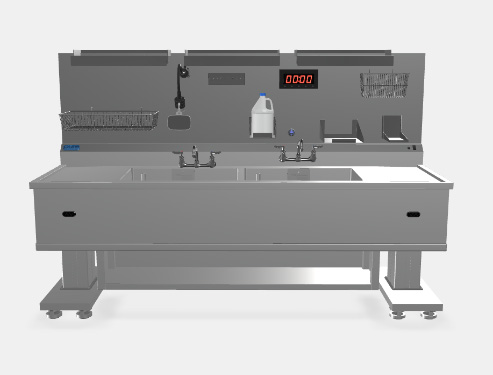

PureSteel™ Healthcare Reprocessing Sink

Engineered by sink experts who understand the reprocessing space, PureSteel Healthcare Reprocessing Sinks are the comprehensive stainless steel sink choice for reprocessing departments.

Learn More

- PureSteel XI Reprocessing Sink

- QuickSonic™ Sink System

- PureSteel Endoscopy Sinks

- PureSteel™ EZ Gate Hinge™ Pegboard

- PureSteel Volume Indicator Etching Plate

- PureSteel™ Workflow Plates

- PureSteel™ UV LED Blacklight Light Hood

- Pure LandingPad Sink & Surface Liners

- PureSoak Waterproof Timer

- PureSteel Organizational Back Wall Panels

- Paladin® Evolution Rail System

- PureSteel™ Copper Clean® Anti-Microbial Wrist Rest

- Tables & Work Stations

PureSteel™ Ergonomic WorkStation

PureSteel™ Ergonomic Workstations are sterile processing workstations designed to maximize efficiency, ergonomics, and compliance in SPD.

Learn More

- PureSteel™ Robotics WorkStation

- PureSteel™ Loaner WorkStation

- PureSteel™ Low-Temp Sterilization WorkStation

- PureSteel™ Signature Series Ergonomic WorkStations

- PureSteel Wrap Inspection Table

- PureSteel™ Mobile Scale Cart

- PureSteel Mini Inspection Table

- Inspection Technology

- Cleaning Chemistries

- Safety