Are you “Robotics-Ready”? Preparing your department for robotic IFU requirements

With advancements in technology and better patient outcomes, robotic surgery has become one of the most rapidly growing specialties in the United States. From 2012 to 2018, robotic surgery cases increased from 1.8% to 15.1% (1). If these devices are not in your department yet, they may be soon.

If your department is preparing to start robotic device reprocessing for the first time, or looking to improve existing practices, it can be confusing to pick a place to start. One of the best places to begin is with instructions for use (IFU). Following device IFUs is essential for two main reasons:

- For the patient’s safety. Contaminated devices can lead to hospital associated infections and surgical site infections for patients. It is sterile processing’s duty to ensure that their medical devices are cleaned properly to reduce these infection risks.

- For your staff’s safety. When cleaning medical devices, sterile processing staff can be exposed to harmful chemicals and be at risk of injury. By following device IFUs, the risk to central sterile staff can be reduced.

However, even with IFU guidance, many departments struggle with shared reprocessing challenges. Common issues that departments run into might be:

- Sink basins which are too small or short to accommodate robotic arm length

- Sink basins being used to accommodate the 30-minute soak time, creating bottlenecks at the sink

- Trouble cleaning difficult-to-reach areas on robotic arms, as arms cannot be taken apart for thorough cleaning

- Ensuring arms are not being reprocessed after their maximum use

- Poor manual cleaning practices, and/or over-reliance on ultrasonic cleaning to perform manual cleaning

- Drying and assembly or robotic instruments, which require up to 4x magnification

Let’s examine some of these challenges in more detail, and potential areas to start improvements or implement efficiencies.

Manual Cleaning & Flushing

Many technicians make the mistake of assuming that ultrasonics can replace manual cleaning for robotic instruments. However, there are several steps that need to happen prior to using an ultrasonic cleaner.

An ultrasonic cleaner’s IFU typically requires manual removal of bio-burden before its use. Soaking a robotic instrument takes 30 minutes alone, however, it then needs to be flushed, sprayed, brushed and rinsed all prior to being placed into an ultrasonic cleaner.

It’s also easy to make mistakes during flushing, as arms have two ports, and for its laborious, time-consuming process. Flushing with a syringe is inefficient, and a spray gun does not ensure the pressure being flushed through the lumen (robotic devices have a pressure requirement during manual flushing of 30 psi).

Consider implementing improvements in manual flushing to improve throughput and efficiency.

Soaking

Many departments face challenges with soaking. Either their basins are too small to properly orient and fit robotic arms, or the sink basins which can fit their arms require the sink to be tied up for the 30-minute period, causing bottlenecks for other instruments to get processed.

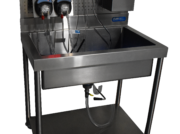

For situations like this, it may be time to think of implementing a 30-inch basin, minimally, or cart to your department. Ensuring that the device can fit inside the sink basin can minimize the risk of damage to the device as well as ensure proper soaking and flushing. Mobile carts also offer the advantage of freeing up precious sink basin space.

Whether it’s a new sink or a mobile cart, a dedicated soaking space will allow your workflow to continue while ensuring robotic IFUs are being met.

Visual Inspection

While cleaning robotics properly is essential to patient safety, these instruments also need to be inspected after cleaning. The best way to inspect any instrument is to utilize a task light at the decontamination sink. Doing this at the reprocessing sink allows technicians to catch contaminated devices before they are sent to the clean side.

Robotic arms should also be visually inspected on the assembly side of the department. To properly inspect these devices, ensure it is entirely dry and inspect it for soil and damage. Cracked and damage housing, residual debris, bent or broken jaw tips, or damaged cables are all points of focus when inspecting robotic arms. Magnifiers with at least 4x magnification are often recommended. Check your IFU for guidance on the power required to inspect hard-to-see areas.

Whether you already reprocessing robotic arms or are in the process of implementing a robotic program, addressing these common challenges can better ready you for their arrival to your department.

You may also consider the following questions:

- Is my staff trained and up-to-date on robotic IFU? Do they understand the inherent challenges, and are confident in reprocessing these devices?

- Is my decontamination department outfitted to address flushing, soaking, ultrasonic, and visual inspection considerations?

- Can I meet robotic IFU requirement at every station, and by every technician?

For any department reprocessing robotic devices or planning to reprocess them in the future, it is important you stay up to date on current IFUs and ensure all steps are being met properly.

Whether it’s tackling flushing multi-port robotic arms, or implementing sinks with can accommodate the length of robotic devices, Pure Processing is prepared to discuss your robotic reprocessing challenges, and ensure you are robotics-ready!

Additional Sources

[1] M. D. Kyle H. Sheetz, “Trends in the adoption of robotic surgery for common surgical procedures,” JAMA Network Open, 10-Jan-2020. [Online]. Available: https://jamanetwork.com/journals/jamanetworkopen/fullarticle/2758472#:~:text=The%20use%20of%20robotic%20surgery%20increased%20from%201.8%25%20in%202012,CI%2C%201.9%25%2D2.3%25). [Accessed: 04-Feb-2022].