The Cost of Commitment – Injuries in SPD

Ask any sterile processing professional and they’ll tell you: there’s a lot of ways to get injured in SPD. That came into crystal clear focus in our 2023 SPD State of the Industry Survey when 47% of participants reported having been injured during their time in sterile processing. It’s a clear demonstration of their commitment to patient safety, even with high personal costs.

While there were some unique circumstances, many participants reported similar injuries across the country. Below is an assessment of common risks technicians are facing daily in SPD.

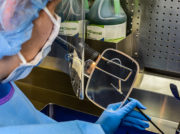

Punctures & Cuts

From K-wires to box cutters, there’s no shortage of ways for technicians to experience cuts or punctures, and it shows. Punctures and cuts from sharps was the leading cause of injury reported by our survey participants. Indeed, Infection Control Today notes that approximately 25% of sharps injuries occur to downstream non-users1.

The sources of punctures and cuts were varied:

- Needles

- K-wires (pins)

- Burr left on drills.

- Drill bits

- Skin hooks

- Sutures

- da Vinci scissors

- Knives

- Box cutters

- Various instruments

Unfortunately, punctures and cuts come with the territory in SPD, but that doesn’t mean the risk can’t be mitigated to an extent. Thicker gloves can help avoid punctures that result in cuts, and enhanced lighting at sinks can improve visibility to help ensure technicians know what instruments their handling.

Communicating with the OR about effective pre-cleaning, or the state of case carts can avoid unnecessary exposure to sharps hazards not meant to be processed in SPD.

Strain

Many participants cited various forms of strain as a primary source of injury within sterile processing departments. Repetitive motion was mentioned the most, sometimes leading to carpal tunnel syndrome. In some instances, surgery was necessary.

When it comes to repetitive motion associated with flushing instruments, automated flushing systems can be a hand and wrist saver; eliminating the repetitive motion required to syringe flush. For the repetitive motions that can’t be remedied with technology, it’s important to ensure your team is trained on the safest ways to conduct these movements, such as lifting heavy objects, and offering braces and supports to help avoid straining. Rotating personnel throughout the week so individuals aren’t over-exerting themselves can provide recovery time.

Overweight trays were a notable source of back and shoulder strain, with technicians noting that overweight trays caused unneeded exertion in ergonomically challenging positions, such as lifting above their head or from below their knees. Loaner and vendor trays were particularly problematic in this category.

Slip & Falls

Slipping and falling was another top source of injury in SPD, primarily in decontamination where sinks and water are omnipresent. Leaky washers, overflowing sinks, poor lighting, and bad housekeeping were all cited as reasons behind slips. One technician broke their elbow from a fall on a wet floor in decontamination!

Luckily, it’s possible to address some of the frequent cause of slips:

- Mats can help technicians avoid slipping on wet floors. Further, anti-fatigue mats provide ergonomic benefits for technicians that need to stand at a workspace for extended periods of time. However, mats which slip should be immediately removed from use, and well monitored.

- Overflow prevention drains in some modern decontamination sinks allow the basin to fill up to a suitable level for rinsing, soaking, and flushing, but drain excess water to prevent overfills. These drains can allow technicians to turn on the water to fill basins, without fear of flooding floors.

- Additional lighting at sinks is a terrific way to improve visibility in decontamination. Lighting can be implemented in many ways, including light strips below the sink, light hoods above the sink, and task lights fitted to pegboards or walls. A good sink partner can also help your department implement additional lighting in customized ways to maximize visibility and help avoid hazards.

2023 SPD State of the Industry Report

Interested in learning about some of the less common dangers technicians reported dealing with in their sterile processing departments? Sign up to receive our 2023 SPD State of the Industry Report once its published to dive into everything participants had to share!

The SPD State of the Industry Survey is an annual, free, anonymous survey asking real sterile processing professionals across the country about their experiences, backgrounds, and challenges they face in their departments. We hope by providing access to free industry research and data, instrument reprocessing professionals can better grow, develop and improve their own departments through the experience of their peers. We are grateful for all the professionals who participate each year, and the contributions to their patients and facilities: thank you for all you do!

Works Cited

1 https://www.infectioncontroltoday.com/view/behind-curtain-sharps-injury-prevention-and-device-reprocessing