Two Departments, One Sink: A Discussion of How Design Impacts Reprocessing Outcomes

Meet Imani and David.

Both Imani and David have been managing their respective sterile processing departments. Both worked their way up from technicians into management, they attend their local chapter meetings, and periodically get together to collaborate on common issues. It’s ideal that both are also in need of decontamination renovations at the same and can collaborate. With the plan to add robotic procedures at both their facilities, some serious changes would need to be made to accommodate the new devices and their IFU.

On top of new ultrasonics and cleaning implements, Imani and David have sourced a potential sink which can meet many of their initial needs. The sink is height-adjustable, it has three basins, and includes some space for organization.

While David and Imani share many things in common, their situations are quite different. Good design is not necessarily universal. Its most basic definition is to, “plan and make decisions for a specific use or purpose”. While David and Imani’s sink choice is well-designed, it is not done so around their specific use or purpose. Their design choice may lead to both intentional and unintentional impacts.

Let’s examine how this one sink design impacts their project outcomes.

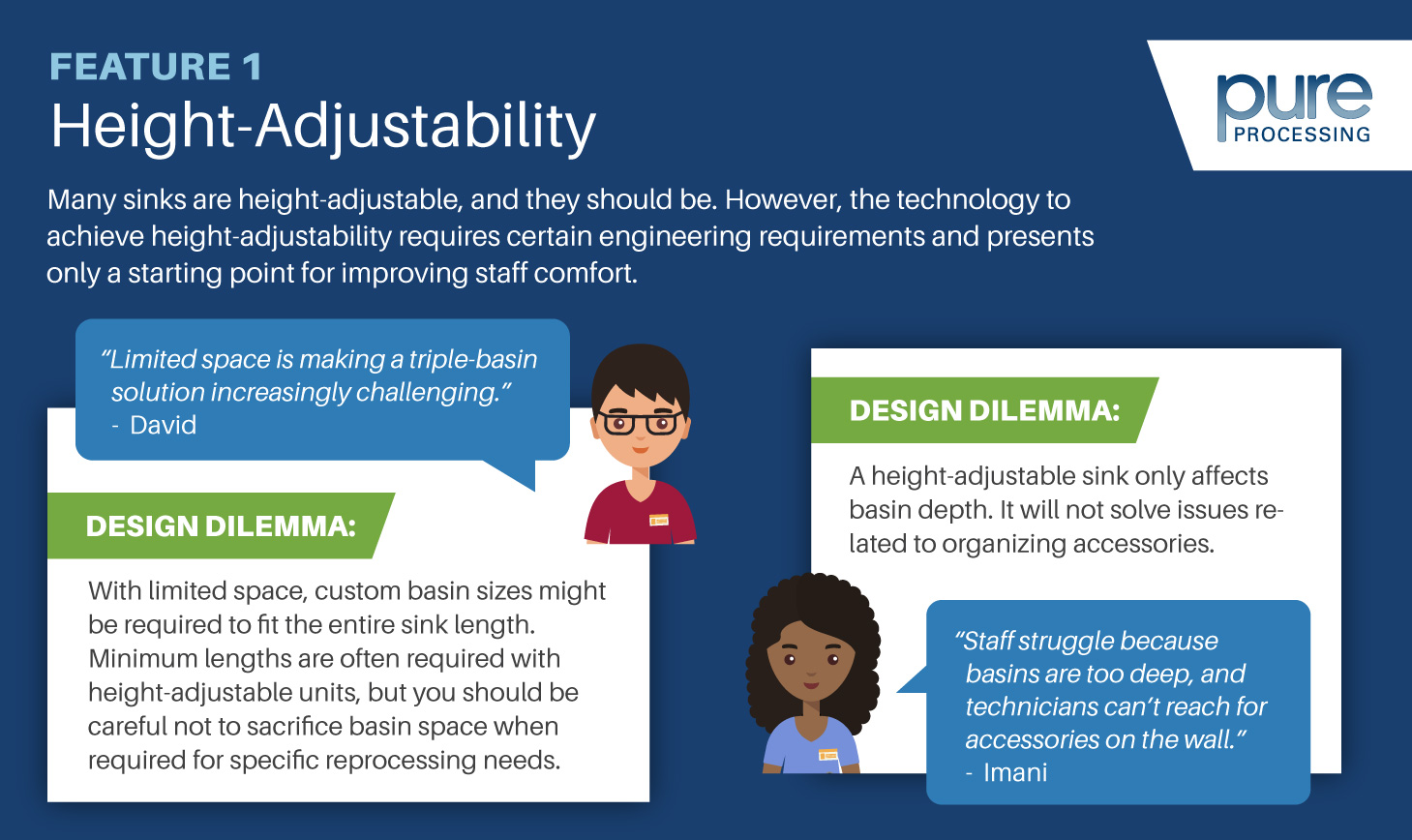

Height-adjustability & ergonomics

Recommendation:

Consider looking beyond height-adjustability to achieve ergonomic benefits. For example, many sink models also include organization that adjusts up and down with the sink, to keep all accessories at a user’s most ergonomic height.

Look for customizable features, like basin space and length, to fit height-adjustable units into smaller footprints. Vendors should be aware of basin requirements for instrument specialties like orthopedic and robotic.

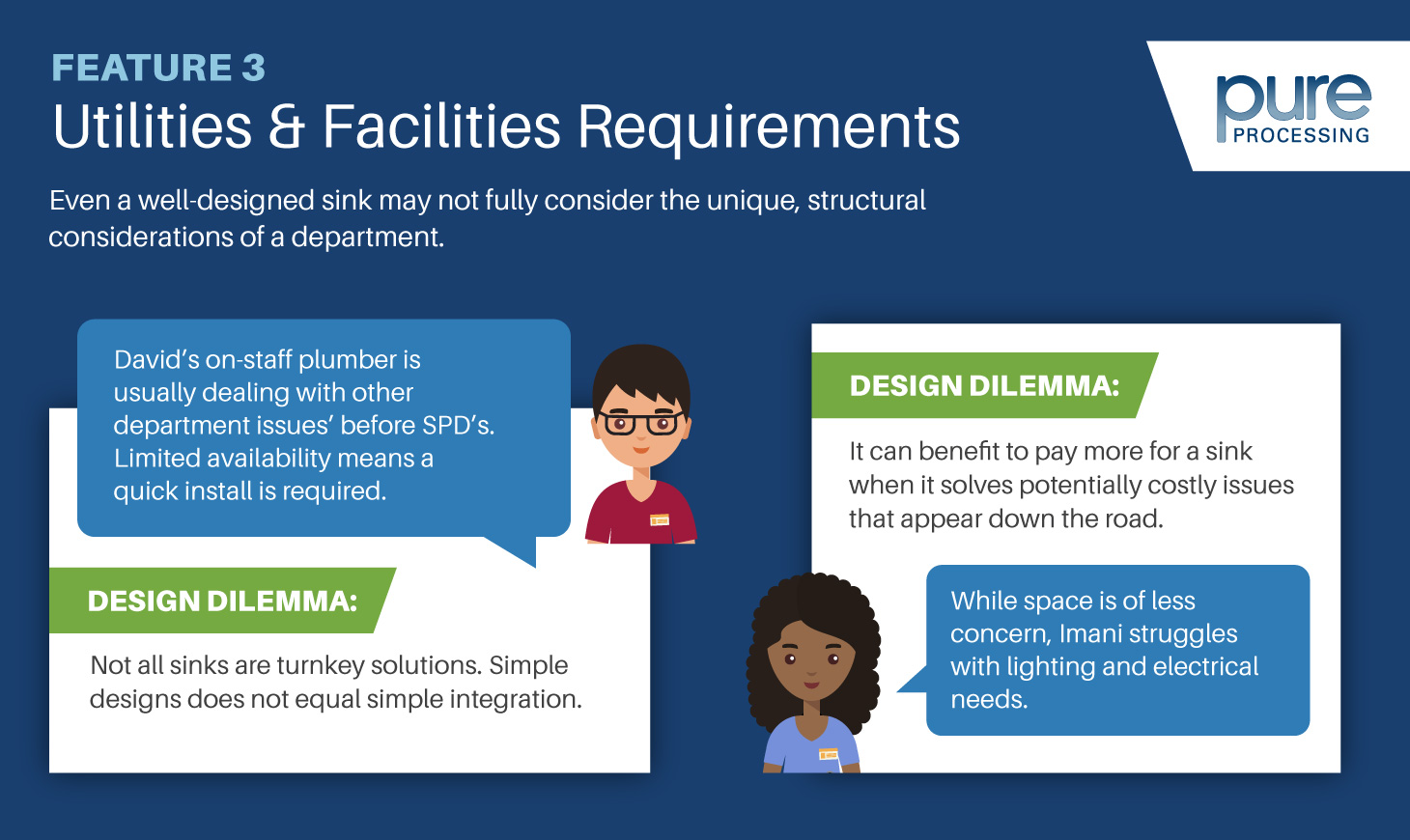

Accessories & integrations

Recommendation:

Organization is unique to every department. David might consider if his sink choice will help him create all-in-one sink stations that can both store and organize cleaning supplies. By mapping out a potential workstation, including required electrical, water and air supplies, David could identify other elements to add to his sink.

Imani may have found the right basin sink, but what about features to meet flushing requirements? Or visual inspection protocol? Sinks can be more than just triple-basin stations; the right sink vendor can integrate all the necessary tools for IFU compliance.

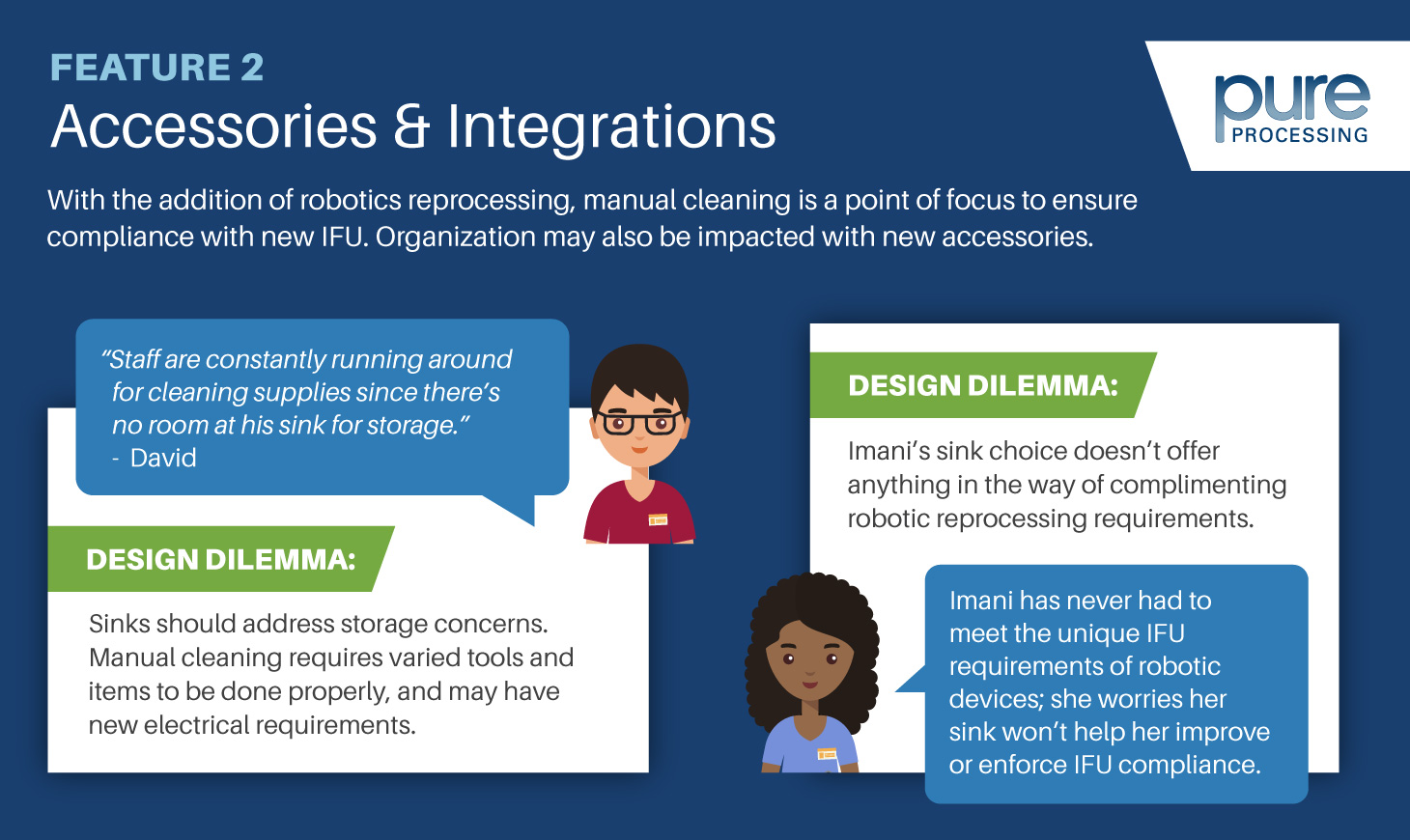

Utilities & facilities requirements

Recommendation:

A well-designed sink goes beyond showy features. Sinks must be connected to plumbing, plugged into walls, and fit into unique spaces. Consider a sink that can have pre-plumbing work done, like telescoping drain systems, to make plumbing installation easier and cheaper.

Some sink options also include built-in electrical outlets, adding capacity to departments with little to none.

Lighting is also critical. See if your sink choice has built-in options, or accessories which can increase visibility at the cleaning station.

While it’s clear David and Imani have a lot in common and can collaborate with each other, their shared sink choice may not have the right design for either of them.

For managers considering a new reprocessing sink, locating a provider who can collaborate, design and engineer a solution for their unique, current needs, and potential future plans, may be a critical piece of the puzzle.

Pure Processing partners with managers, project planners, architects, and reprocessing professionals to build a sink solution that works for them and their objectives. Contact us to learn more about our consultation process and our reprocessing sink solutions.