Workstation Disorganization: Problems and Opportunities

We have all seen it: an assembly table or workstation disorganized and in disarray. Many departments operate this way every day, but what problems arise from that disorganization, and what opportunities are there for a department to improve?

Lack of space

There are many tools and materials needed at a typical workstation. While they’re all necessary,  they can get in the way if they are not given a deliberate, permanent home. It is difficult to assemble a rigid container if there’s a keyboard on it. It’s also hard to inspect an instrument if your monitor is obscuring your magnifier.

they can get in the way if they are not given a deliberate, permanent home. It is difficult to assemble a rigid container if there’s a keyboard on it. It’s also hard to inspect an instrument if your monitor is obscuring your magnifier.

These tools suddenly become hindrances. It’s like allowing fans to watch a basketball game from the middle of the court. Setting up a workstation or table in a way that allows easy accessibility to tools and materials – while also keeping them neatly out of the way when not in use – enables technicians the space necessary to do their job without leaving their workspace.

Lack of focus

Inspecting and packaging requires immense attention to detail; not only does everything need to be executed flawlessly to ensure patient safety, but the correct materials and equipment need be employed based on the types of instruments and the sterilization processes they require. Any number of small things can go wrong.

Inspecting and packaging requires immense attention to detail; not only does everything need to be executed flawlessly to ensure patient safety, but the correct materials and equipment need be employed based on the types of instruments and the sterilization processes they require. Any number of small things can go wrong.

Imagine you want to impress your spouse with a homemade dinner. You would probably get all of your ingredients together, organize them, and use them in the order necessary to create a fantastic meal. Now imagine every ingredient you own was strewn about the kitchen. It’d be tough to know where to start, right?

The same sense of chaos can stem from an unorganized table or workstation. It’s important that there is a methodical, focused approach to determining what items go where. If not, technicians waste time focusing on what to grab next from where, and less on the task at hand.

Spending more time without a process

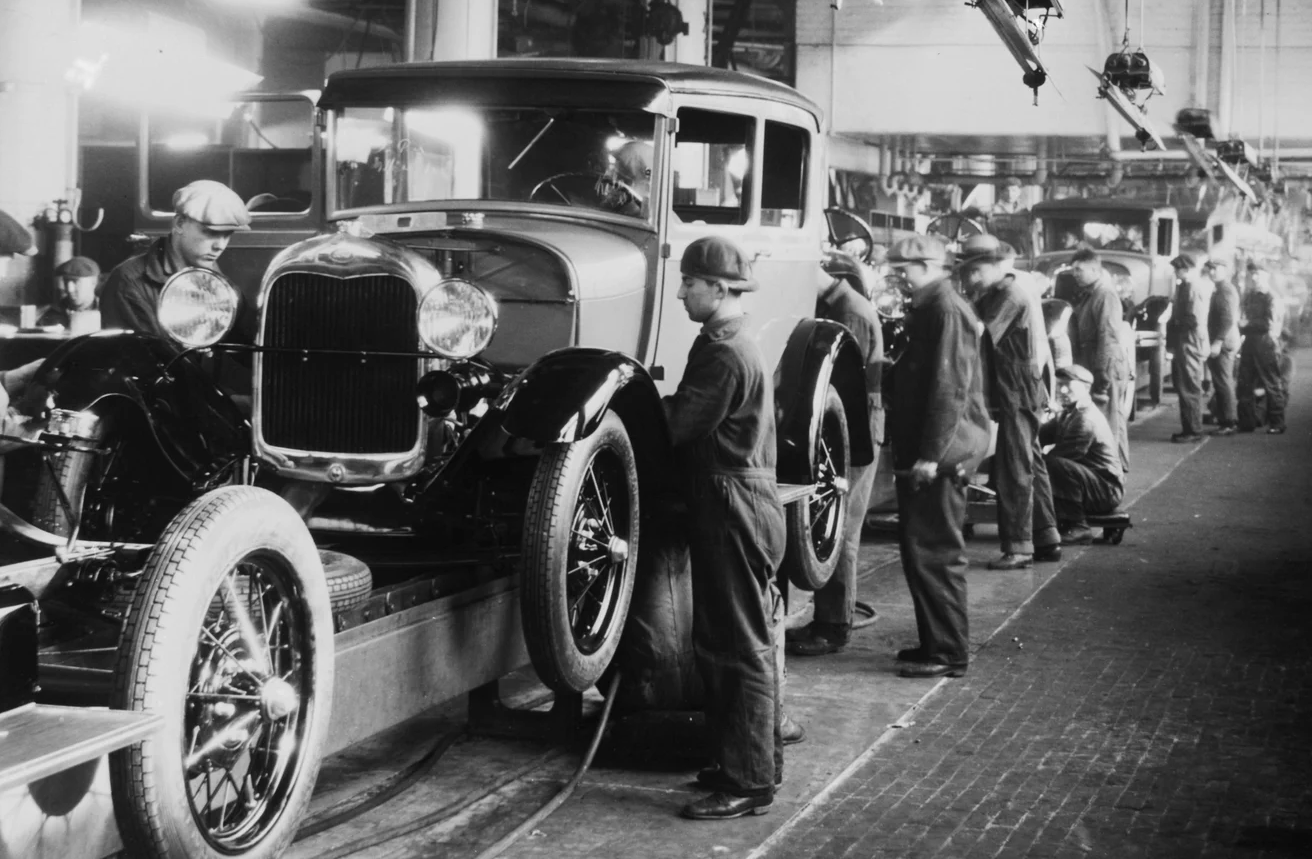

Needing to search for the equipment a technician needs can do more than just divert their focus; it can slow them down considerably. A good process produces good results, and good processes require organization. After all, it was an industrial level of organization that made Henry Ford’s production line so successful.

than just divert their focus; it can slow them down considerably. A good process produces good results, and good processes require organization. After all, it was an industrial level of organization that made Henry Ford’s production line so successful.

By organizing the factory and its’ resources in a way that guaranteed one step was easily completed before the next, Ford was able to produce cars faster than ever while maintaining a consistent level of quality.

Tables and workstations can benefit from the same level of organization. Configuring a workstation to allow for a streamlined, predictable workflow – with all components readily available – enables a technician to not only produce high-quality results but do it more efficiently and consistently.

Centralization

Let’s revisit that meal you’re going to make to impress your spouse for a moment. The first thing you would probably do is gather your ingredients. You head to the fridge for a protein and vegetables, then to the pantry for some pasta, and finally grab a few spices from the cabinet. Next, you’ll need your pots and pans, so you grab those from another cabinet. After a few minutes in your kitchen, you’re ready to start cooking.

Let’s revisit that meal you’re going to make to impress your spouse for a moment. The first thing you would probably do is gather your ingredients. You head to the fridge for a protein and vegetables, then to the pantry for some pasta, and finally grab a few spices from the cabinet. Next, you’ll need your pots and pans, so you grab those from another cabinet. After a few minutes in your kitchen, you’re ready to start cooking.

Now imagine the fridge is in the bathroom, the pasta is in the garage, the spices are in the basement, and the pots and pans are in a shed in the backyard. Getting ready to make dinner just became a nightmare, and you are probably going to get distracted along the way.

Just like it makes sense to have everything you need to make dinner in the kitchen, it makes sense to put everything a technician needs at their prep and pack table. Each time they are required to go and get something, they are breaking their focus, wasting time, and opening the door to potential distractions.

F.A.N.

Functional, accurate, neat; we are all familiar with the FAN principle. To create an ideal workstation for a technician in SPD, apply the FAN principle:

Functional – Workstations are organized in a way that technicians have the tools and the space needed to perform every function of their role.

Accurate – The materials needed to prep various instruments for sterilization are readily available at the workstation.

Neat – The workstation is organized to facilitate a streamlined, easy-to-use process that allows technicians to consistently produce high-quality results.

“I don’t have the space…”

Most departments lack adequate space, due to sterile processing services being an afterthought in the hospital design process, and an increase in complexity and throughput requirements for sterile processing.

For reprocessing professionals struggling with this issue, not to worry. Check out Elevate Your Workspace to find out how your department can get on the path to more organized, efficient, and ergonomic workstation setups. If you’re interested in getting an outside perspective to help solve an organizational problem you department is facing, we’d love help out!