Sink Organization’s Role in Streamlining Workflows

As we discussed in our blog post, Disorganization Dilemma – Reprocessing Sinks, a lack of organization around reprocessing sinks can be detrimental to a department’s training/onboarding initiatives, productivity, or compliance against IFU & patient safety. But, if there’s a problem, there’s an opportunity to improve!

Here are a few methods to organize a sink that can help your department improve outcomes:

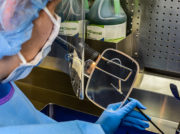

Pegboards

Pegboard back walls add a new dimension to the organization of reprocessing sinks and are often a first step towards improving processes and workflows. The customizable, modular nature of pegboards means that they can be fitted with whatever sterile processing technicians & GI nurses need, right where they need it.

For departments that haven’t used an organizational pegboard before, introducing one is like giving an artist a canvas for the first time; they suddenly have a space they can configure in a multitude of ways, laying out equipment and materials not where they can, but where they want and need to.

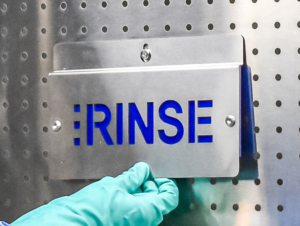

Workflow etch plates

Another great option to create intuitive sink organization? Workflow guidance.

Indicator plates are simple in concept but big on impact. By visually identifying each area of a reprocessing sink, sterile processing and GI managers accomplish a few things:

- Lay the groundwork for further organization and customization

- Enable new team members to easily learn your department’s processes

- Demonstrate that distinct areas are designated for specific reprocessing tasks, something The Joint Commission is likely to look for in a survey

Shelving

Adding shelving to your sink’s pegboard brings storage to a whole new level, literally. While some sinks have shelving or cabinets mounted above them, they may prove difficult to access or entirely inaccessible for shorter technicians. If a team member needs to request help or find a step stool to access storage above the sink, a considerable amount of time is added to the completion of their work, not to mention safety hazards associated with slip and falls.

Shelving options that have open configurations and are easily cleanable is also important to consider. Closed cabinetry and shelving can harbor bioburden, and are often too large or deep for most staff to clean properly.

Chemistry bottle holders

Chemicals, such as disinfectants and enzymatic detergents, are required for a wide array of tasks in reprocessing departments. Bottle holders for these chemistries mounted directly to a sink’s pegboard keeps them readily accessible and easily visible, ensuring that they’re available when needed, and replaced when running low. Placing bottle holders near dosing pumps also makes it easy to drop in leads and have a ready supply of whatever chemical is required.

Timers

Many IFUs require specified amounts of time for certain tasks. While a small, standalone timer is often used to manage these tasks, it is easy for those timers to be misplaced or forgotten about. This can result in wasted time, an inability to accurately time certain tasks, or insufficient cleaning time per a device’s IFU.

for those timers to be misplaced or forgotten about. This can result in wasted time, an inability to accurately time certain tasks, or insufficient cleaning time per a device’s IFU.

Mounting a large, backlit, highly visible timer at each area of a reprocessing sink where required enables team members to accurately soak devices for the required amount of time and keep tabs on how much time is left, ensuring that IFUs are met, and time isn’t wasted. Timers with alarms may also be available. As most central sterile departments become loud during peak reprocessing times, built-in alarms keep tasks on pace, and prevent oversoaking or over-exposure to chemistries.

Other tools and equipment

There are myriad of tools and equipment that departments can implement to help their team accomplish their tasks in a streamlined, efficient manner; these examples are just a small handful. The problem is that they can often clutter the working area at the sink, leading to departments either under utilizing the tools managers purchase, or opting not to acquire useful tools because there isn’t room for them.

Tools such as flushing systems, magnifiers, and inspection scopes can be easily affixed to a pegboard, allowing departments to leverage previously underutilized space and bring game-changing tools to where technicians and nurses need them.

Optimizing the way your reprocessing sinks are organized is a low-cost, high-impact project that can lead to immediate results in terms of process improvement, throughput, and even ergonomics.

If you’re interested in exploring ways to better organize your reprocessing sinks, let us know!