Supporting Surgical Robotics Programs: The Robotics Reprocessing Toolkit

From journals like The New England Journal of Medicine and The Lancet refusing to publish information about the “seemingly incredible nature of robots assisting with surgery”1 in 1997, to the majority of minimally invasive surgeries being conducted via robotic-assisted surgery in 20202, Intuitive Surgical®’s robotic surgical platforms have been sweeping the healthcare industry in the U.S. over the last 20 years, and that growth is poised to continue at a rapid pace in the coming years.

Unfortunately, the same investments made by healthcare facilities to implement new, or additional robotic surgical volume, doesn’t often extend to sterile processing departments, causing them to take on an influx of sophisticated surgical devices without additional tools or personnel to do it.

How can the addition of appropriate tools and equipment turbo-charge a sterile processing department supporting a surgical robotics program?

Automated flushing systems

Flushing requirements of robotic instruments are one of the most laborious aspects of their reprocessing instructions for use (IFU). Not only do they contain time and volume requirements, but there are also two, sometimes three, ports that need to be flushed. Each additional port doubles, or triples, the flushing time required per device compared to single port devices, leading to lengthened reprocessing times and bottlenecks.

Automated flushing systems enable technicians to flush each port simultaneously, significantly reducing time spent flushing. Further, automated flushing systems ensure that the appropriate volume of solution is flushed per device IFUs, meaning compliance comes at a much lower cost in time spent and repetitive motion.

automated flushing systems ensure that the appropriate volume of solution is flushed per device IFUs, meaning compliance comes at a much lower cost in time spent and repetitive motion.

The most guesswork (and human error) often comes from ensuring 30psi is met during robotic lumen flushing. Automated flushing systems ensure that the 30PSI flushing requirement is met consistently for all ports; this is often impossible to meet or validate with syringes.

The benefits of automated flushing systems go beyond ergonomics, productivity, and compliance. With SP robotic devices requiring two-handed manipulation of wrists and joints while simultaneously flushing ports (seemingly impossible to do all at once), an automated flushing system can be securely connected to allow technicians to freely manipulate joints according to IFU.

As the sophistication of robotic arms increases, manual flushing is likely to become a of thing of the past in modern sterile processing departments.

Sink, basin, and soaking solutions

Two other significant concerns are the length of robotic arms and their extensive soaking requirements.

The length of robotic devices has been a concern in departments due to inadequate basin size of many older sinks currently in use. Narrow basins lead to an inability to fully submerge the device, causing compliance concerns as well practical cleaning issues.

Soaking requirements also create problems in sterile processing departments that haven’t received the budget to prepare for reprocessing robotics. With long soak times, robotics tie-up sink basins and slow down throughput at the sink.

Transporting robotic instruments can be challenging, but transport containers, such as the InstruSafe XL Transport Container, solves transportation and soaking concerns. An ideal size for soaking and protecting your valuable instruments, it offers a standalone soaking basin solution for larger instruments, with a lockable, dry-erase lid to note the start time. Additionally, it’s cart washer safe and includes water volume indications and bio-hazard labels for a complete soaking system.

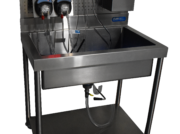

Limitations associated with space plague many departments, making the implementation of new, fixed equipment challenging. Mobile solutions bring the benefits of an additional basin capable of fitting a robotic device without giving it a permanent location in the department. With casters, a pegboard to mount tools, and a small footprint, the PureSteel™ Mobile Soaking Station is streamlined for robotics reprocessing in a package that can be deployed and removed from the department as needed, saving precious space without forfeiting capabilities.

While a sterile processing department may not receive a sink upgrade with the implementation of a robotics program, smaller and more targeted solutions can help tremendously. Small, dedicated sinks, such the PureSteel™ XI Reprocessing Sink, can kill two birds with one stone:

- The 28” sink basin comfortably submerges da Vinci robotic arms

- A dedicated standalone sink doesn’t bog down other reprocessing sinks from their workflows

With the addition of a pegboard to organize automated flushing systems, a dosing pump and soaking timer, PureSteel™ Xi Reprocessing Sinks can get a department back to the productivity levels required while fully supporting their facility’s robotics program, at a small cost relative to that program.

Robotic surgery is an exciting, innovative part of the modern surgical landscape and is likely to continue expanding and evolving. It’s vital that sterile processing’s tools, equipment, and capabilities evolve alongside it.

Need to get your department prepared for a robotics program implementation? We’d love to help!