Aging Sinks and Workstations Put Compliance at Risk

Sterile processing and GI staff work hard to get every detail right. When the fixtures and furniture at the heart of cleaning and inspection are past their prime, compliance becomes harder to achieve and even harder to sustain.

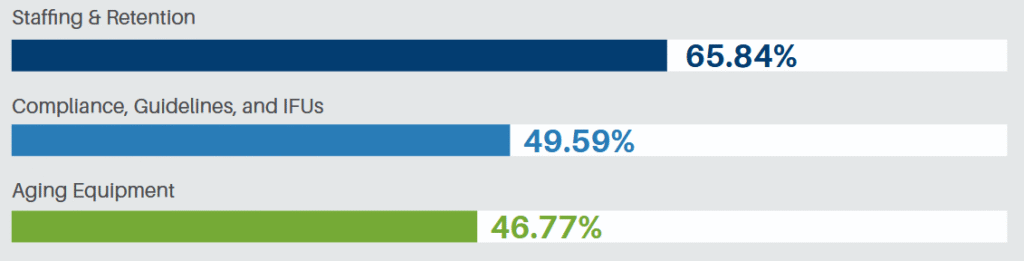

The 2025 Sterile Processing State of the Industry data shows that aging equipment is not a niche concern. Nearly one in four respondents prioritized equipment issues among the most important problems to solve, and almost half expect aging equipment to intensify as a future challenge.

Below is a practical look at how older sinks and workstations can undermine compliance, what to watch for, and steps you can take right now.

Aging Equipment Erodes Compliance

Big Idea: Manual cleaning loses consistency when sinks are undersized, in disrepair and at capacity.

Outdated sinks often lack accurate temperature control, and the depth or basin configuration needed for safe immersion and rinsing. That makes it harder to carry out IFUs consistently and results in inadequate reprocessing and poor practices. For example, when robotic arms do not fit into the sink basin, they cannot be fully submerged and adequality exposed to cleaning chemistry for the IFU required amount of time giving risk to leaving bioburden behind or damaging the instruments.

Sinks in disrepair pose a risk for staff injury and exposure. When height adjustability features don’t work, basins are too deep or there are leaks in the plumbing sterile processing teams lack the resources needed to compliantly and safely do their jobs. When pipes leak, drain systems fail or sinks deteriorate, staff can be exposed to stagnant water, bacterial growth and slip and falls hazards when standing water collects on the floor.

Big Idea: Poor lighting and inadequate inspection tools hide defects.

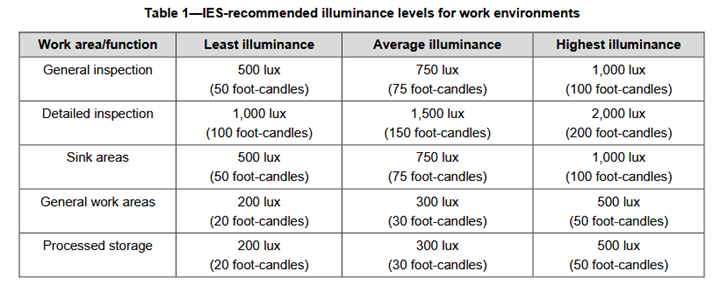

Dim work surfaces reduce visibility of soil, damage, and other organic residuals. ANSI/AAMI ST79 3.3.5.6 gives luminosity recommendations based on area of work, type of work and age of employee. There is a higher illumination requirement at inspection work areas that support visual checks and detailed inspection. If the lighting at your workstations does not reach the illumination rating for inspection areas, defects such as pitting, misalignment, and residual bioburden are more likely to slip through.

Big Idea: Missing or outdated magnification and visualization tools increases rework and risk.

Older workstations without integrated magnification, borescopes, or stable power for lighted magnifiers make it difficult to achieve the enhanced visual inspection that current guidance encourages, especially for lumened and complex devices.

Ofstead and Associates’ Lumen 2.0 study indicates that there were 100% findings across lumened instruments . Some of the noted disreapirs included:

- Scratches

- Residues & Soils

- Fibrous Debris

Big Idea: Fixed-height counters and sinks result in awkward reach zones that drive fatigue that can degrade technique.

Fixed equipment leads to shoulder and back strain and potentially shortcuts at the sink or table by staff. ANSI/AAMI ST793.3.6.1.1 gives recommendations on ergonomic and productivity considerations when configuring sinks and workstations that support proper manual cleaning and inspection while reducing injury risk. Our survey respondents also rated ergonomics and What to look for during a quick walk-through

- Sink basins that are too shallow for immersion or too narrow for trays

- Dripping faucets, unstable spray arms, or leaking under sink plumbing

- Broken or unused magnification and task lights

- Ergonomic workarounds and poor posture

- Overcrowded work areas with outdated resources and information

Navigating through the challenges

Assess and prioritize.

Document IFU steps that are hard to execute with current resources. Capture illumination, and ergonomic pain points. Tie findings to rework, delays, and staff injury trends from your department.

Shore up the process.

Addressing lighting, magnification, basin accessories, and simple ergonomic aids first can greatly improve quality outcomes and boost staff morale as work continues to drive improvements in more capital required upgrades

Replace the bottlenecks.

When upgrading sinks and workstations, choose basin dimensions that support full immersion and rinsing, plan splash protection that preserves dirty-to-clean separation, and specify height adjustability or better fit for your team.

Sustain with education

Use micro in-services to keep technique aligned with IFUs and to reinforce changes.

Aging sinks and workstations do not only slow technicians down. They increase the chances of inconsistent cleaning, missed defects at inspection, and documentation gaps. Our 2025 survey data shows that equipment concerns are already pressing and expected to grow, which makes a clear plan to stabilize and modernize the decontamination and assembly environment essential for compliance and patient safety.

Interested in digging into other key findings from the 2025 Sterile Processing State of the Industry Report? Download it here!