Seeing the Light: Visualization Challenges and How to Tackle Them

Sterile processing departments are rarely given premium placement in a hospital. Many departments are in lower, interior areas where lighting isn’t optimal or able to be controlled. So much so, that industry guidelines specifically emphasize it. ANSI/AAMI ST79:2017 states:

“Ancillary lighting should be considered for areas where instruments are manually cleaned and inspected. Lighting fixtures should be selected and mounted in positions that focus the light in front of the employee so that they are not working in their own shadows.”

- ANSI/AAMI ST79:2017 3.3.5.6 D

What are some challenges sterile processing departments face related to lighting, and how can those challenges be remedied? Let’s shine a light on that!

The Problem: Poor overhead lighting

Departments often rely on in-ceiling fluorescent lighting. While it has been a standard for a long time, and many professional workplaces rely on them, they are generally not adequate for sterile processing departments, where optimal visibility is necessary to not only do their work but do it safely.

The Solution: Lighted Shelving

Lighted shelving units are the ideal way to remedy overhead lighting issues. Attaching them to either sinks or prep & pack tables enables departments to give working areas adequate lighting quickly, while simultaneously providing additional storage space above the work area.

The Problem: Inspecting Blue Wrap

Technicians in prep & pack have long struggled with inspecting wrap for punctures, perforations, and holes. Many technicians will hold the wrap above their head against the overhead lighting to see if any light shines through holes or imperfections. Not only is this method unreliable, but it also poses ergonomic concerns with consistent arm raising throughout the day.

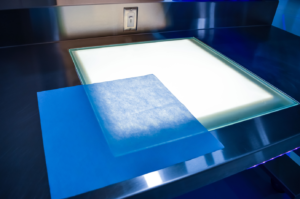

The Solution: Tabletop Lighting

High-quality workstations and prep & pack tables now offer built-in tabletop lighting. There are many benefits to integrated lighting this way, including:

- Direct contrast against the light source: the blue wrap is directly against the tabletop light, making it easier to spot imperfections in the wrap and ensuring consistent quality of inspection.

- Tabletop lighting brings the light source to an ergonomically-friendly position for the technician, reducing strain and ensuring comfort throughout their shift. When coupled with height adjustable lifters, workstations with tabletop lighting can transform prep & pack for technicians.

The Problem: Underwater Visibility During Cleaning

Technicians in decontamination deal with a wide array of instruments, surgical tools, and occasionally scopes at their sinks. Many cleaning tasks are required to be performed underwater to reduce splashing and aerosols. Unfortunately, visibility within their sink basins is often poor, with a minimal amount of light able to penetrate the water and shadows blocking what light there might be. This can lead to avoidable punctures, as well as inadequate inspection of scopes during leak testing.

The Solution: In-basing Lighting

In-basin lighting provides a benefit other lighting cannot: shining it directly on its source of action, and from a secondary angle. By bringing lighting into the basin, technicians don’t run the risk of casting shadows over it, or otherwise blocking the limited lighting in their department. Further, in-basin lights offer high visibility of scopes during leak testing by illuminating under the surface of the water, making air bubbles easier to spot.

The Problem: Inspection of Instruments

Visual inspection of instruments in SPD is one of the first lines of defense for patients undergoing surgery. A technician spotting that dull blade before it makes it the OR can have a substantial impact. Unfortunately, workstation lighting doesn’t always offer optimal conditions for visual inspection of instruments, allowing inadequate instrumentation to make it into trays.

The Solution: Task Lights

Dedicated task lights at both sinks and prep & tables allow technicians to conduct exceptional visual inspection of the instruments coming through SPD, improving the quality of the trays the OR receives, as well as patient care. With integrated magnifiers, task lights literally take it to the next level when compared to inspecting unassisted. The best part? Task lights are able to be mounted to pegboard back walls, affording sterile processing departments all of the benefits task lights provide, without cluttering or using the limited space available in SPD.

Illuminating Opportunities

With so many areas to incorporate supplemental lighting solutions, there’s no shortage of opportunities to enhance your department, improve ergonomics, and deliver and exceptional patient experience.

Looking for input or help to improve the lighting in your department? We’d love to help you out!

Interested in learning about ways to get your prep & pack workstations more organized? Check out our blog post: Workstation Disorganization: Problems and Opportunities