2025 Sterile Processing State of the Industry Report: Actionable Insights

The annual Sterile Processing State of the Industry Report offers a powerful snapshot of what frontline teams are facing nationwide. With insights from over 700 SPD professionals, this year’s report is packed with real-world experiences and hard-earned wisdom. Based on these findings, here are actionable strategies leaders can implement today to drive meaningful change.

Find great people where they already are

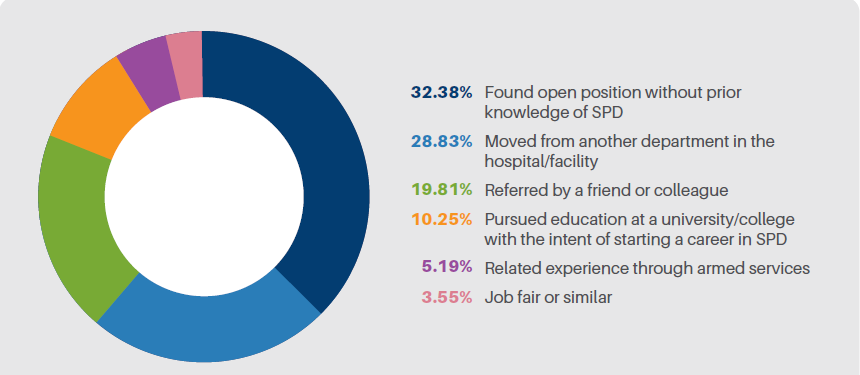

Many professionals still discover SPD through internal pathways or personal networks. In 2025, 60.00% reported entering SPD by moving from another area in their facility, through a referral, or by deliberately pursuing the field. Meanwhile, 32.38% found an open role without any prior knowledge of SPD.

Actionable insight: keep external recruiting active, but also tap internal departments and your team’s networks for candidates who fit.

Build around what SPD pros enjoy most

Free-response themes highlight why people love the work: helping patients and making a difference, contributing to surgery and patient safety, hands-on technical work, teamwork, continuous learning, purpose, and job stability.

Actionable insight: reflect these motivators in job postings, onboarding, recognition programs, and career ladders to attract and retain aligned teammates.

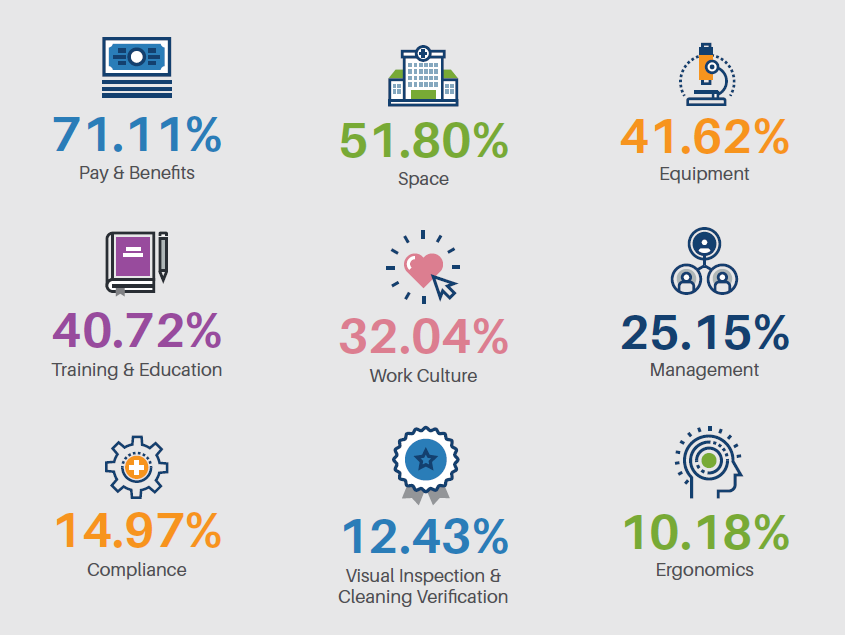

Turn the most common problems into focused projects

Top reported problems in 2025 were Pay and Benefits 71.11%, Space 51.80%, Equipment 41.62%, Training and Education 40.72%, Work Culture 32.04%, Management 25.15%, Compliance 14.97%, Visual Inspection 12.43%, and Ergonomics 10.18%.

Actionable insight: address one domain per quarter and publish a simple plan with owners, dates, and outcomes so the team can see progress.

Quick wins the team believes are fixable

When asked what should be easy to resolve today, respondents pointed to Workplace Culture and Professional Respect 28%, Training and Education 22%, Pay and Benefits 21%, Equipment and Preventive Maintenance 12%, Communication, Teamwork and Management Support 12%, and Compliance and Standards 5%.

Actionable insight: standardize monthly huddles, set and share a rolling in-service calendar, update preventive maintenance schedules, and close the loop on suggestions in writing.

Prioritize the “most important” problems first

The issues participants said matter most for departments to solve were Equipment Issues 22.70%, Training, Education and Competency 15.40%, Pay and Benefits 15.00%, Culture and Work Environment 14.00%, Leadership, Communication and Accountability 8.80%, Space and Layout 8.60%, Staffing, Retention and Compensation 8.20%, and IFUs, Compliance and Policies 7.40%. Culture carried a notably higher share of frustrated sentiment, which suggests cultural problems can cascade into other challenges.

Actionable insight: pair an equipment improvement plan with culture, communication, and accountability commitments so processes and people move together.

Improve training outcomes by naming an owner

Training and Education ratings are higher when an Educator drives the program. Where the Educator was named most influential, Training and Education averaged 6.5, compared to Manager 6.0, Director 6.3, and Supervisor 5.8.

Action items: name an owner, protect time for frequent micro in-services, tie each module to specific IFUs or SOPs, verify competency, and share a simple “you said > we did” update monthly.

Use department ratings to focus improvements

Average ratings this year: Compliance 6.9, Leadership 6.7, Visual Inspection 6.7, Workflow and Processes 6.5, Work Environment 6.5, Technology 6.4, Ergonomics and Technician Comfort 6.3, Culture 6.0, and Training and Education 6.0.

Actionable insight: if Compliance is strong but Training and Education or Culture lag, link education efforts directly to policy adherence and celebrate wins to reinforce culture.

Modernize record-keeping and explore AI where it helps

Record-keeping methods in 2025: Pen and paper 35.58%, Digital 15.22%, Combination 49.20%. Year over year, pen and paper dropped by roughly 4 points and digital rose by just over 4. AI adoption sits at 7.85% yes and 92.15% no, with use cases in tracking integration, inventory, inspection tech, analytics and reporting, content creation, and task management.

Actionable insight: move from pen and paper to hybrid, then from hybrid to fully digital to make the transition easier . Pilot one AI-assisted task where you already have data, like analytics roll-ups or study guide generation tied to your SOPs.

Reduce injuries with targeted prevention

41.43% reported being injured at some point in their SPD career. Common mechanisms include cleaning and handling sharps 11.4%, lifting and moving heavy items 7.1%, and hot equipment or steam 4.1%. Actionable insight: reinforce sharps handling, add lift aids or team-lift standards for heavy trays and carts, and review hot set handling procedures. Track incidents and share fixes.

Prepare now for the next wave of challenges

Respondents expect greater pressure around Staffing and Retention 65.84%, Compliance, Guidelines and IFUs 49.59%, Aging Equipment 46.77%, AI introduction 31.84%, Instrument Complexity 30.35%, Volume 26.87%, and Technology 26.04%. Actionable insight: budget for equipment replacements on a multi-year timeline, keep competency work tied to specific devices and IFUs, and plan change management around any new technologies.

Click here to read the full report, explore all the insights, and earn 1 Free CE.