Resolving Small Problems in SPD and GI

In a previous post, Small Problems with a Big Impact on Patient Safety, we discussed how seemingly insignificant concerns seen in SPD & GI departments can have considerable impacts on processes and quality outcomes, ultimately resulting in risks to patient safety. With those issues and their ramifications identified, it’s logical to wonder, “okay, now what?”

Let’s dive into some of the simple solutions that departments can deploy to combat these small problems.

Adhesives

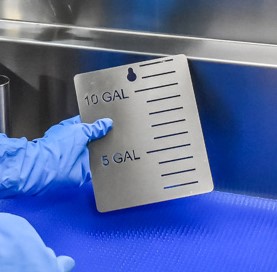

Many departments use adhesives in applications such as water line markers and temporary temperature strips, resulting in a risk of residual bioburden. Stainless steel volume indicator plates can quickly eliminate the use of water line stickers. With a relatively simple installation, these plates not only deliver a reliable visual to indicate how much water is in the basin, but their stainless steel construction allows them to be put through a cart washer for deep and easier cleaning. This means the days of maintaining and replacing temporary water line stickers are gone, with assurances that the plate is always ready for use after a trip through the cart washer.

Temporary, adhesive temperature stripes can also be eliminated through sink design. Integrated thermometers within sink basins ensure accurate, reliable temperature measurements via high-visibility LED gauges built into pegboards. This takes gauging temperature to the next level, ensuring that the team can easily determine whether water temperatures are outside of optimal ranges.

Bioburden

Residual or undetected bioburden can have wide-ranging consequences for patients. Every SPD and GI professional strives to eliminate all bioburden on and within the devices they reprocess. Even with the best of intentions, the human eye can only achieve so much; it’s challenging to know what you missed if you can’t actually see it.

Borescopes are being implemented in departments across the country. With advances in catheter diameter and visualization technology, their importance is growing each day. Implementing borescopes for visual inspection can help teams get their eyes into places they previously couldn’t, illuminating bioburden that may have been otherwise missed. With compact computers and varying monitor options able to be mounted to pegboards or dedicated visualization stations, visual inspection via borescopes is more feasible than ever.

For external inspection, magnified task lights provide the necessary illumination and up-close perspective needed to spot bioburden and damage before the instrument moves on. Some task light options even offer the ability to swap out lenses with varying magnifications, enabling teams to tailor the tool to their need. Consider task lights with at least 4x magnification, which meet a range of IFU and are better at inspecting complex devices.

Leak Testing

The critical nature of leak testing means that success (or lack thereof) has a big impact on departments and patients alike. Visualization plays a significant role, with most staff relying on the naked eye to visualize leaks. This means that adequate lighting is the key to helping technicians and nurses do this job well.

Hood lights mounted above the sink are an excellent first step towards providing the illumination required for the job. While the benefits of these lights extend well beyond the basin, their role in leak testing is notable.

Taking it a step further, sink design can take in-basin lighting to the next level in form of integrated LED basin lights. In-basin lighting eliminates the risk of shadows impeding visibility while conducting leak tests, as well as helping teams pinpoint the source of bubbles and, ultimately, the location of damage within devices such as endoscopes.

Sinks Equipped with Electrical Capabilities

Many sinks aren’t designed with the power requirements for end-users’ tools and accessories. This results in an inability to justify the purchase of these products, or abandonment of them after purchase, not only wasting money, but depriving teams (and patients) of the benefits these tools provide.

Considering the current and future power requirements that will be needed at decontamination sinks in the design phase can ensure that sinks have ample power supply and an ability to accommodate your department’s need now and later, when guideline and IFU changes may fuel new needs.

There are countless small problems that pop up in SPD and GI departments that can seem insignificant on their face but have the ability to create significant problems for patients if not resolved. Vendors see these and take them seriously, with many options developed to tackle these kinds of problems head-on. Whether it’s something as simple as volume indicator plates, or something that requires a little more planning in the design phase of equipment like sinks, there are ways to tackle these problems, help protect patients and providing your team with effective tools in the process.

Interested in learning about other challenges seen at decontamination sinks? Check out our blog: Common Problems at Sinks in Reprocessing Departments today!